US claims magnetic refrigeration advance

29th March 2018USA: Researchers in the US claim to have made a breakthrough in achieving refrigeration-level cooling by using very small quantities of magnetocaloric materials.

Staff at the US Department of Energy’s Ames Laboratory claim that the development marks an important step in creating new technologies to replace gas compression refrigeration with solid-state systems up to 30% more energy efficient.

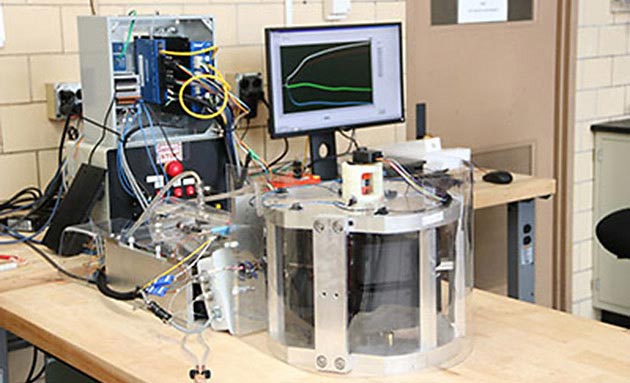

Called CaloriSmart – Small Modular Advanced Research-scale Test-station – the system was designed specifically for the rapid evaluation of materials in regenerators without a large investment in time or manufacturing.

The initial test subjected a sample of gadolinium to sequential magnetic fields, causing the sample to alternate between heating up and cooling down. Using precisely timed pumps to circulate water during those heating and cooling cycles, the system demonstrated sustained cooling power of about 10W, with a 15ºC gradient between the hot and cold ends using only about 3cm3 of gadolinium.

“Despite predictions we would fail because of anticipated inefficiencies and losses, we always believed it would work,” said CaloriCool project director and Ames Laboratory scientist Vitalij Pecharsky, “but we were pleasantly surprised by just how well it worked. It’s a remarkable system and it performs exceptionally well. Magnetic refrigeration near room temperature has been broadly researched for 20 years, but this is one of the best systems that has been developed,” he claims.

The system, which took roughly five months to build, used 3D printing technology to custom-build the manifold that holds the sample and circulates the fluid that actually harnesses the system’s cooling power. The system also features customised neodymium-iron-boron magnets that deliver a concentrated 1.4Tesla magnetic field to the sample, and the precision in-line pumping system that circulates the fluid.

“We only need 2-5cm3 of sample material – in most cases about 15-25g,” explained project scientist Julie Slaughter. “We are setting the benchmark with gadolinium and we know there are other materials that will perform even better. And our system should be scalable (for commercial cooling) in the future.”

“But the main reason we conceived and built CaloriSmart is to accelerate design and development of caloric materials so they can be moved into the manufacturing space at least two to three times faster compared to the 20 or so years it typically takes today,” added Pecharsky.

The team maintain that magnetocaloric testing is just the beginning. The plan is to upgrade the system to work with elastocaloric materials – that reversibly heat up and cool down when subjected to cyclic tension or compression – and electrocaloric materials – that do the same when subjected to changing electric field. It is said that the system will even operate in a combined-field mode that allows a combination of techniques to be used simultaneously.

“There are a handful of places studying elastocaloric and electrocaloric materials, but nobody has all three in one place and our system now gives us that capability,” ”Pecharsky claims.