Hubbard trials liquid-air-powered refrigeration

5th June 2014UK: Suffolk-based Hubbard Products is collaborating on field trials of a new liquid-air-powered transport refrigeration system.

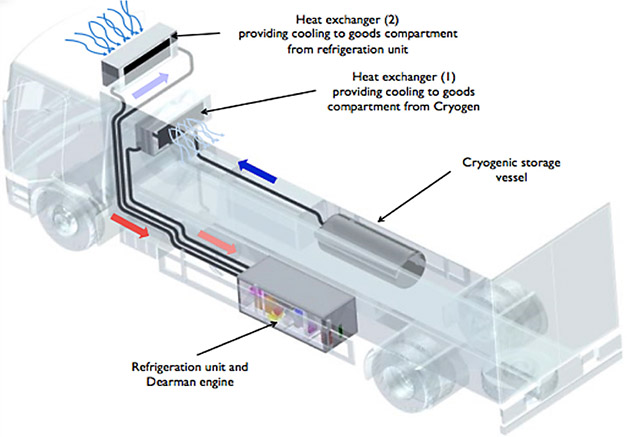

The Dearman engine is a novel piston engine powered by the phase-change expansion of liquid air or nitrogen. The developers claim that It will deliver major reductions in carbon, local air pollution, noise and cost. In the early years it will be fuelled from spare nitrogen production capacity.

It works on the basis that liquid air – a liquid at temperatures below -194°C at ambient pressure – can be conveniently stored in insulated but unpressurised vessels. Exposure to heat – even ambient temperatures – causes rapid re-gasification and a 700-fold expansion in volume, which can be used to drive a turbine or piston engine.

The addition of waste heat from, say, an internal combustion engine will increase the work that can be extracted from the expansion of liquid air. That expansion also gives off large amounts of valuable cold, which can provide ‘free’ refrigeration or air conditioning, or be used to increase the efficiency of diesel engines or hydrogen fuel cells.

Hubbard and Dearman have signed a memorandum of understanding to develop the technology to a stage where Hubbard can manufacture, integrate and market cooling systems incorporating the Dearman engine in commercial volumes.

The initial objective is to deliver five field-trial prototypes of the refrigerated vehicle system to a UK end user early next year. Dearman is said to be already engaged in discussions with two major supermarkets.

The intention is for Dearman to supply the engine systems and Hubbard the refrigeration equipment combined with off-vehicle systems integration elements.

The process of liquefaction of air is a mature process used for many years in industrial processes to produce liquid nitrogen or liquid oxygen. In addition to the huge environmental benefits, liquid air itself is seen as a potentially very important energy storage technology.

The Dearman engine will be inexpensive to build, will be low maintenance and have low environmental impact, exhausting only cold air.

The Dearman Engine Company (DEC) was formed in 2011, with the engine being named after its inventor Peter Dearman. The technology has received more than £4.5m of grant funding to date.