Engineers rise to off-grid refrigeration challenge

27th May 2020USA: Seven initiatives to develop affordable refrigeration technologies in the developing world have been selected for grants ranging from $30,000 to $50,000.

The winning projects have been announced by Engineers Without Borders USA (EWB-USA) in its Chill Challenge initiative launched last year.

The Chill Challenge seeks to support affordable refrigeration technologies for off-grid households in the developing world. Seen as having enormous potential for improving the lives of millions of the poorest and most vulnerable people on the planet, off-grid refrigeration means less food waste, more opportunities for farmers and improved nutrition for households. In addition, as highlighted by the COVID-19 pandemic, refrigeration is critical for delivering vaccines and other health care services to remote off-grid communities.

The following teams will be awarded grants ranging from $30,000 to $50,000 to develop their innovative concepts:

Purdue University, Ray W Herrick Laboratories, West Lafayette, Indiana, USA

Cold storage battery for domestic refrigeration

This project will evaluate the use of heat from clay or brick cookstoves to drive an intermittent sorption refrigerator, which requires no electricity to operate.

The generated refrigerant does not need to be immediately discharged, but can instead be stored and expanded later to provide cooling on demand.

In charging mode, a heat source is used to generate refrigerant which is stored for use during discharging. In discharging mode, the refrigerant is expanded to create cooling on demand. The cold storage battery is designed to be used alongside existing wood-fired cookstoves, although other fuel sources could be used including solar thermal energy.

New Leaf Dynamic Technologies, New Delhi, India

Ice maker powered by farm waste

New Leaf has developed, and is currently deploying, its GreenChill ammonia refrigeration system to provide safe storage and cooling of perishable agricultural produce.

The system is powered by farm-waste such as straw, cow dung, biomass pellets, wood and hay, etc, and can cool up to 1,500 litres of milk or 15 tonnes of perishables goods without the need for electric grid power or diesel generator backup.

New Leaf estimates that the system will need about 105kg of wood equivalent biomass per day to produce 1000kg of ice. The system will also require about 500W of electrical supply to run auxiliary equipment, which will be provided by solar PV with battery backup.

More than 25 systems have been installed in locations across India.

Under this grant, the company will use its GreenChill technology to build a 1000kg/day ice maker to produce ice at a cost of 0.02 US$/kg.

Arup, London, UK

Passive cooling box

Consultant Arup’s advanced digital engineering team will test a refrigeration system using passive cooling materials that emit heat as infrared radiation through the atmospheric transmission window into space. Phase change materials will provide cold storage.

Arup has investigated the use of passive cooling materials in the built environment and, in partnership with housing nonprofits, is working to scale up deployment of reflective roofs in developing countries.

Under this grant, Arup proposes to build a completely passive cooling box capable of achieving the 3°C target temperature and maintaining that temperature across several days of adverse weather conditions.

The container will rely on radiative cooling materials as a cold source and phase change materials as cold storage.

Radiative cooling materials are solid-state materials designed to emit heat, in the form of infrared radiation, through the “atmospheric transmission window” into space.

Recent research has developed materials that are also highly reflective of sunlight, which permits them to cool themselves well below ambient temperatures, day and night, without any electricity or refrigerant required. It has been demonstrated that these materials can cool themselves substantially below 0°C when “parasitic” heat flows are minimised.

Xergy Inc, Harrington, Delaware, USA

Off-the-grid refrigerator utilising solid-state refrigerants

To address the off-grid refrigeration challenge, Xergy will build a refrigerator utilising an intermittent adsorption refrigeration cycle driven by solar thermal energy.

The unit will use hydrogen and metal hydride as the working pair, and employ an advanced heat exchanger design, which the company believes will result in an efficiency of 70%.

The system will store hot water to provide refrigeration for “dark days” without solar input. If successful, the team believes the refrigerator would provide a simple, easy to maintain solution for remote off-grid communities. Xergy has also proposed using the same refrigeration process in an icemaker.

Solar Cooling Engineering, Hohenheim, Germany

Solar ice maker using key components and engineering

The team from Solar Cooling Engineering, in collaboration with the University of Hohenheim, has been carrying out research on solar cooling for the last six years. Their work has included a solar ice maker developed for milk cooling, with 18 systems deployed in Tunisia, Kenya and Colombia.

Since 2018, the company has been promoting the use of SelfChill, solar cooling units which can be combined with locally produced refrigeration cabinets to provide flexible and lower cost refrigeration solutions in communities in developing countries.

For the Chill Challenge, Solar Cooling Engineering will use its SelfChill solar cooling units in an icemaker capable of producing 100-120kg of ice per day. These units use DC direct-drive vapour compression technology with R600a (isobutane).

The ice maker is powered directly by PV panels or, optionally, with electrical batteries. The provided control unit integrates a smart algorithm to command the compressors in dependence of solar energy availability.

A Bluetooth smartphone connection is included for monitoring, and the system is fully pay-as-you-go enabled.

Purdue University, Ray W Herrick Laboratories, West Lafayette, Indiana, USA

Combined Heating and Cooling for Agricultural Applications

This research will examine the potential for using a combined heating and cooling vapour compression system to produce ice and to dry crops.

While vapour compression refrigeration systems have a high initial cost, a combined system, which uses the evaporator capacity to create ice and the condenser heat to dry crops, may provide a way to offset that cost.

The research will evaluate food drying and storage practices, including their prices and seasonality. Potential applications of the technology will then focus on locations that produce food items that command high value and/or are available throughout the year, as these will provide more benefits than seasonal food items.

The team proposes to build a system that generates 100-150kg of ice per day, using a vapour compression cycle with R290 (propane) as the refrigerant and solar PV as an energy source.

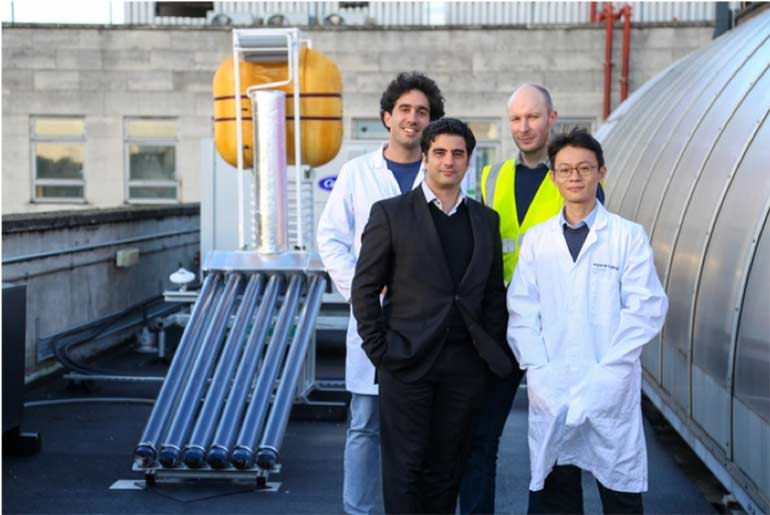

Imperial College London, Clean Energy Processes (CEP) Laboratory, South Kensington, UK

Affordable decentralised off-grid ice making

The CEP Laboratory at Imperial College London and Solar Polar have been developing a thermally powered technology, called diffusion absorption refrigeration (DAR), which can be easily integrated with low-cost solar thermal collectors or that utilise waste heat to provide cooling. The simple construction and lack of moving parts of DAR devices promise low costs and long lifetimes.

Under this grant, the CEP team proposes to design and demonstrate an innovative, affordable ice maker based on DAR technology. The team will replace the ammonia-water pair typically used in DAR devices with alternative working-fluid pairs in optimised unit designs. The team expects that these innovative designs of the device and the molecular design of the new fluids will enable a COP almost 1.5x higher than that of conventional ammonia-water systems. Based on this technology, the CEP team proposes to build a simple, robust and affordable ice maker using hot water from solar-thermal collectors, specifically aimed at developing, remote or off-grid communities.

Challenge attracts 43 entries

The Chill Challenge was launched in September 2019, to solicit innovative proposals for more affordable refrigeration for off-grid communities. In response, EWB-USA received 43 proposals from 36 teams from universities, companies or NGO’s, and individuals. Sixteen were US-based, and 20 were located overseas, including teams from Cameroon, Ethiopia, France, Germany, Nigeria, South Korea, Switzerland, Uganda and the UK.

Fourteen of the best proposals were shortlisted, and final grant winners were selected by a panel of reviewers, including EWB-USA volunteers and international refrigeration experts.

Engineers Without Borders USA was formed in 2002 to harness the power of engineers to complete high-impact projects in developing countries. Since then, EWB-USA has grown from a handful of passionate individuals to thousands of passionate volunteers working on hundreds of engineering projects across the globe.