Bubble control at the flick of a switch

28th October 2015 USA: A way of controlling the the boiling process, independent of temperature, could produce significant improvements in cooling and heating system efficiencies.

USA: A way of controlling the the boiling process, independent of temperature, could produce significant improvements in cooling and heating system efficiencies.

The process of boiling water, with its commotion of bubbles that rise from a surface, is central to a host of industries, and none more so than in cooling and heating. Researchers at MIT claim to have found a way to control this process, literally with the flick of an electrical switch.

The system is described in a paper by Department of Mechanical Engineering Professor Evelyn Wang, graduate student Jeremy Cho, and recent graduate Jordan Mizerak, published in the journal Nature Communications.

This degree of control over the boiling process, independent of temperature, Wang says, has not previously been demonstrated despite the ubiquity of boiling in industrial processes. Other systems have been developed to control boiling using electric fields, but these have required special fluids rather than water, and a thousandfold higher voltages, making them economically impractical for most uses.

The new feat was accomplished by adding surfactants to water — essentially creating a soapy liquid. The surfactant molecules, which carry an electrical charge, can be attracted to, or repelled by, a metal surface by changing the polarity of the voltage applied to the metal. This switches the metal surface between being hydrophilic (water repelling) and hydrophobic (water attracting), Wang explains.

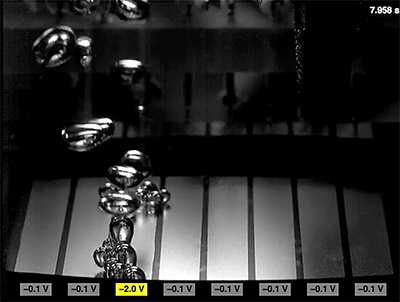

Adding the surfactant causes the surface to become more hydrophobic, which increases the rate of nucleation to form bubbles. But reversing the charge on the surface causes the surface to become hydrophilic, and inhibits the formation of bubbles. The researchers found that they could achieve a tenfold change in the rate of bubble formation simply by switching the charge.

Just as condensation, such as the formation of raindrops, requires a “seed,” like a dust particle, to start the process of nucleation, the bubbles formed by boiling water also require nucleation. Tiny irregularities on a metal surface can provide those nucleation points, but if the surface is hydrophilic the formation of bubbles is inhibited.

“The whole concept relies on the fact that whether a surface is hydrophobic or hydrophilic will affect the rate of nucleation,” Cho says. “If it’s hydrophilic, it’s very difficult to nucleate bubbles.” So by switching the polarity, the rate of bubbling can be precisely controlled.

Unlike other approaches to modifying the wettability of metal surfaces, which rely on the creation of precise kinds of nanoscale textures on the surface, this system makes use of the tiny irregularities that naturally exist on a metal surface and does not require special processing.

Being able to actively control the rate of bubble formation, in turn, allows control over the rate of heat transfer between the metal and the liquid. As a result, the system would enable the optimum rate of heat transfer to be chosen moment by moment.