R404A – the alternatives

26th February 2014 Agreements on the revisions to the European F-gas regulations have finally sounded the death knell for R404A and other refrigerants with GWPs of over 2,500. With the USA looking likely to follow suit, the rest of the world will not be far behind. So what are the alternatives?

Agreements on the revisions to the European F-gas regulations have finally sounded the death knell for R404A and other refrigerants with GWPs of over 2,500. With the USA looking likely to follow suit, the rest of the world will not be far behind. So what are the alternatives?

These new rules targeting the high GWP refrigerants will affect R404A, R507A and R422A (MO79), all of which were substitutes for R22 or R502 and all with GWPs of over 3,000.

The biggest impact will be on users of R404A, a refrigerant widely used in supermarket refrigeration systems and accounting for 46% of worldwide F-gases.

For the record, the relevant proposals – which still need to be ratified by parliamentary vote, but seem likely to get the go-ahead – will bring a ban on fixed refrigeration systems containing HFCs with GWP of 2,500 or above (except for equipment whose operating temperature is lower than -50°C) on January 1, 2020. On the same date a ban will be imposed on hermetically sealed commercial refrigerators and freezers containing HFCs with the same high GWPs. Recycled refrigerants will still be able to be used up until 2030.

In advance of the legislation there has been an undoubted shift towards CO2 by many supermarkets in new systems. In turn, many plug-in commercial cabinet manufacturers are moving from R404A to hydrocarbons but what other options are out there for those keen to retain their existing equipment but concerned with the high pressures or flammability of the natural options?

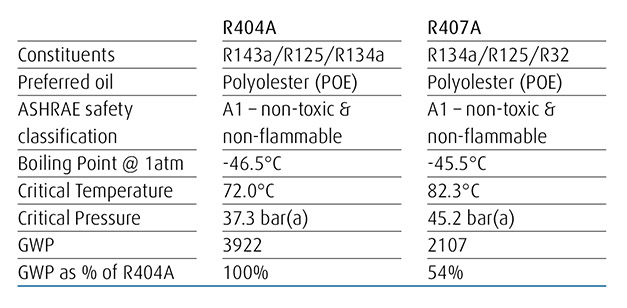

Until now there have been three main replacements for R404A. Two are sister refrigerants to R407C, the initial favourite for use in unitary air conditioning systems using different percentages of the HFC refrigerants R134a, R125 and R32.

These are R407A – a blend of 40% R134a, 40% R125 and 20% R32 – with a GWP of 1990. The other is R407F which favours slightly more R32 to R125 in a blend of 40% R134a, 30% R125 and 30% R32. The extra R32 gives R407F a slightly lower GWP of 1824.

The other option is R442A, formerly known as RS-50, and, again, a blend of 31% R32, 31% R125 and 30% R134a with the addition of 3% R152a and 5% of the fire suppressant R227ea. It has a GWP of 1888.

In addition to these, there are a number of other new or soon to be available refrigerant blends utilising the new HFO refrigerants. These offer lower GWPs. Some are non-flammable and some, with even lower GWPs are of the “mildly flammable” variety. More on these in the second part of this article.

R407A

As with the other refrigerants here, it should be noted that R407A is an alternative replacement refrigerant rather than a true “drop-in”. Also, it is essential to seek further information from your refrigerant supplier and compressor manufacturer(s) before performing a retrofit.

Promoted as an ideal retrofit solution for many existing R404A systems, R407A has been freely available on the market for over twenty years. It is said to be more efficient than R404A and is a straightforward retrofit.

It is compatible with the same oils, elastomers and plastics as R404A and is approved for use by a number of compressor manufacturers. It is said to have a similar cooling capacity to R404A and lower discharge temperatures than other R404A replacements, thus reducing the need for compressor heat protection (liquid injection).

Energy efficiency improvements of up to 10% have been reported with many systems.

The changeover from R404A to R407A is said to relatively easy and in many cases, the original oil can be used.

The changeover from R404A to R407A is said to relatively easy and in many cases, the original oil can be used.

R407A, like other gases in the R407 series, is a zeotrope and must be charged in the liquid phase to prevent fractionation. The glide requires a minor adjustment to the expansion device.

Some suppliers also recommend that you overhaul your refrigeration system during the retrofit operation including the filter drier and seals.

R407F

A slightly more recent introduction to the market, R407F has been adopted by many supermarkets across Europe using R404A systems due to R407F’s improved capacity and energy efficiency.

An area of concern raised initially by compressor manufacturers, is in the application of these alternative refrigerants at very low temperatures (below -35° C). Higher compressor discharge temperatures below these conditions has meant the need in some cases, for some form of additional cooling – coming usually in the form of head cooling fans or liquid injection.

This is not such a significant problem with R407A at low temperatures but R407F manufacturer Honeywell maintains that tight control of system superheat, helps reduce the discharge temperature by anywhere up to 20% on the published or claimed levels.

Compatible with the same oils, elastomers and plastics as R404A, like R407A it is approved for use by a growing number of compressor manufacturers. It has a similar cooling capacity to R404A and improved energy efficiency. Like R407A, R407F is fully compatible with the POE lubricants used in an R404A system and, in many cases, the original oil can be used.

R407F has a lower mass flow than R404A, so some recommend checking existing piping to ensure compatibility. Its higher discharge temperatures than R404A also make it advisable to consult compressor manufacturers to confirm acceptable discharge temperatures.

R407F has a lower mass flow than R404A, so some recommend checking existing piping to ensure compatibility. Its higher discharge temperatures than R404A also make it advisable to consult compressor manufacturers to confirm acceptable discharge temperatures.

Also, like its sister refrigerant, R407F must be charged in the liquid phase to prevent fractionation and a minor adjustment to the expansion device will be required.

Like R407A, it is also recommended that you overhaul your refrigeration system during the retrofit operation including the filter drier and seals.

R442A

According to the manufacturers, R442A is said to show a faster pull down time than any other low temperature refrigerant currently available under dynamic conditions.

It has a higher COP than R404A and increased cooling capacity.

Like the other alternatives it is compatible with POE lubricants and, like 407A and 407F, superheat will need to be checked and adjustments made to the expansion valve.

As previously stated, it is essential to check retrofit procedures with the refrigerant suppliers and establish compatibility with compressor manufacturers.

Compressor manufacturer Danfoss offers advice when considering a retrofit on a system with R404A:

1. First of all, conduct a thorough analysis of the installation and the costs of a retrofit. Take into account the age of the installation and its main components. Estimate how long the installation could still run and which components may require replacement soon. This can strongly influence the choice for the best retrofit process.

2. Take into account that the retrofit in this case could increase the cooling capacity. This is partly due to the thermodynamic properties of the refrigerant. On the other hand, we must consider that the large glide of some blends could reduce the heat exchanger capacity by up to 5%. The change in cooling capacity should be so low that the application design will not have to be changed.

3. Glide training will be relevant; dew and bubble temperatures/pressures can lead to errors when setting up devices.

4. The new refrigerants and POE or PVE oils are fully compatible and do not affect the system components.

5. Retrofitting does not apply to the following specific applications: Installations with flooded heat exchangers, such as tube-&-shell require refrigerants with a negligible glide such as R404A or R507. Blends with large glides must not be applied.

Danfoss also points out that, like many manufacturers, it does not have enough experience with the effect of using these blends in systems which have already contained R404A, and therefore Danfoss does not accept any liability for this use. Danfoss does, however, recommend strict compliance with refrigerant manufacturer instructions and procedures.

Read part ll of this article on the low GWP options:

R404A – the low GWP options – May 5, 2014

With European legislation sounding the death knell for R404A and other countries around the world likely to follow suit with similar bans on high GWP gases, what are the alternatives? Read more…