AI design can reduce heat pump energy consumption

7th July 2019

SWITZERLAND: Artificial intelligence is being used to design next-generation microturbocompressors which could reduce heat pumps’ power requirement by 20-25%.

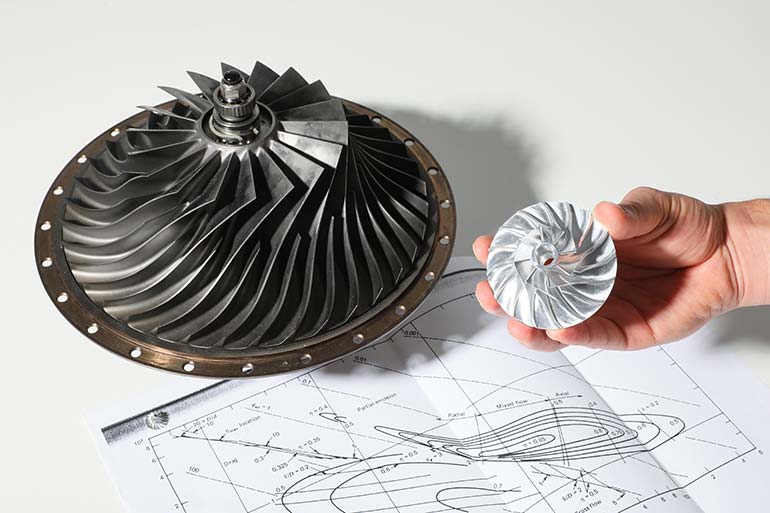

Turbocompressors are more efficient and ten times smaller than piston devices, but incorporating these mini components into heat pumps’ designs is not easy – complications arise from their tiny diameters (<20mm) and fast rotation speeds (>200,000rpm).

Researchers at the Laboratory for Applied Mechanical Design at Lausanne’s EPFL (École polytechnique fédérale de Lausanne) have developed a method that is said to make it easier and faster to add turbocompressors to heat pumps. Using a machine-learning process called symbolic regression, the researchers came up with simple equations for quickly calculating the optimal dimensions of a turbocompressor for a given heat pump.

The researchers’ method is said to drastically simplify the first step in designing turbochargers. This step – which involves roughly calculating the ideal size and rotation speed for the desired heat pump – is extremely important because a good initial estimate can considerably shorten the overall design time. Until now, engineers have been using design charts to size their turbocompressors – but these charts become increasingly inaccurate the smaller the equipment. Also, the researchers argue that the charts have not kept up to date with the latest technology.

The EPFL team fed the results of 500,000 simulations into machine-learning algorithms and generated equations that replicate the charts but with several claimed advantages: they are reliable even at small turbocompressor sizes; they are just as detailed as more complicated simulations; and they are 1,500 times faster. The researchers’ method also lets engineers skip some of the steps in conventional design processes. It paves the way to easier implementation and more widespread use of microturbochargers in heat pumps, they argue.

Paper related to this research are pubished in Journal of Engineering for Gas Turbines and Power.